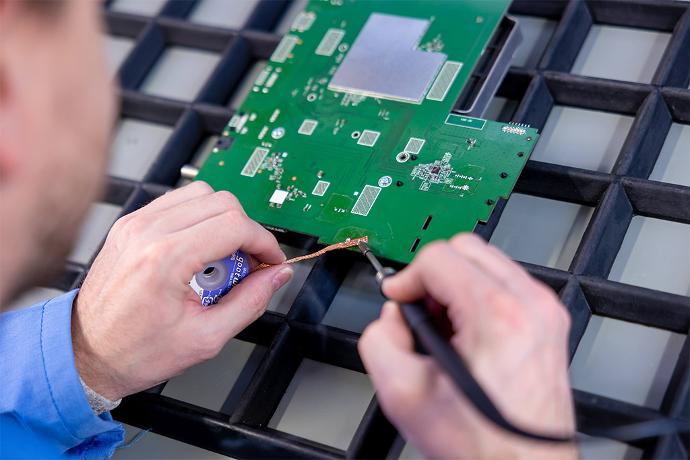

Manufacturing

Build devices, or products according to the specifications provided by the OEM/ODM. This can involve processes like PCB assembling, soldering, testing, and quality control.

Assembly

Assembling various components into a final product. This can include integrating electronic components, mechanical parts, and other elements.

Testing and QC

Ensuring that the products meet quality standards through rigorous testing and inspection processes. This includes functional & performance testing, and optical verification.

Prototyping

Developing prototypes or samples of electronic products to validate design concepts before mass production.

Supply Chain

Managing the procurement of quality materials, components and parts required for production. We ensure that everything is delivered on time.

Logistics

Handling the transportation and delivery of finished products to the OEM/ODM or other specified locations.

Customization

Providing customization options as per the OEM/ODM requirements, which can include branding, packaging, and specific features.

Scalability

Scaling up production to meet the required volume and demand, whether for small batches or large quantities.

Cost Efficiency

Offering cost-effective manufacturing solutions by leveraging specialized expertise and economies of scale.

Collaboration

Collaborating closely with the OEM's engineering and design teams to ensure the products are manufactured to meet the desired specifications.

Subcontracting manufacturing

Subcontracting manufacturing allows OEMs/ODMs to focus on product design, marketing, respond more flexibly to market demands and other core activities, while benefiting from our expertise in efficient and high-quality production.